Products > Microperforated Films

Microperforation Packaging

Flexible films provide a protective function against a wide range of factors, but some products require the ability to breathe while still packaged. Microperforated technology provides a solution to this issue by piercing films with grids of pin-sized holes, thereby adding shelf life and functionality to a wide range of commercial, medical and grocery products.

Helion's microperforated film technology, developed jointly between Australia and China, covers a wide range of materials, hole diameters and grid patterns. Furthermore, Helion is one of the first companies in China to develop custom pin-hole rotary tooling.

How does microperforation work?

Helion has two methods to microperforating films: hot and cold perforation. Hot perforation, as the name suggests, uses heated needles to pierce holes into films. Sleeves of sharp needles are heated to high temperature before the film is pulled over its surface. Upon contact with the heated needles, the film melts and leaves a reinforced hole. Cold perforation pierces film by busting needles through the film to create holes. This method is best suited for elastic films, as brittle films tear under tension. |

|

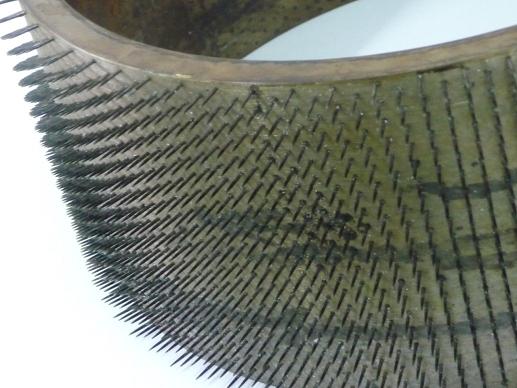

Pinned Rotary Tooling

Tooling used for piercing microperforating films is difficult to manufacture. There is also a lack of competitive manufacturers in the world (most are based in Europe or the U.S.). Helion has developing in-house tooling to bypass these constraints. Tooling can be customised to individual requirements given the following allowances:

-

Needle density

- Minimum diagonal separation = 3 mm

- Maximum Density = 110,000 needles/m2

- Minimum hole size = 0.5 mm (500 um)

- Max Web Width = 1400 mm

Pinned Rotary Tooling

We perforate into the following films:

| Microperforated PET (heat sealable) |  |

| Microperforated BOPP | |

| Microperforated LDPE | |

| Microperforated HDPE | |

| Microperforated CPP | |

| Microperforated PVC | |

| Microperforated Laminates | |

Markets

Microperforated “Ready to Eat” Packaging:

- Allows "ready to eat" meals to be kept warm in ovens while still packaged

- Pie wrapping and pie film (Commonwealth region)

- Bakery and pizza products

Microperforated Microwaveable Films:

- Product, while packaged, can be frozen and later microwaved (PET)

- Burrito film

- Pie film

Microperforated Bread Bags:

- Avoids bread softening from trapped steam

- Bakery products

- Adds respiration to fruit and vegetables

- Mushroom-packaging Film

- Tomato-packaging Film